powering the

future

CATHODE RAW MATERIAL

ACTIVATION LINE DESIGNER

OUR EV BATTERY ACTIVITY

As part of the global dynamics of electrical mobility, CLEIA’s EV Battery activity meets a crucial requirement: activating cathode materials for batteries.

Armed with our historic expertise in thermal processing operations and product handling, we develop customised solutions including dryers, kilns and handling systems, thus participating in the increase of electrical battery production volumes.

mission

REDUCTION OF RAW MATERIAL COSTS

ENABLING VOLUME INCREASE

FACING CHALLENGES TOGETHER

CUSTOMISED ENGINEERING

TYPES OF PROJECTS

Cathode material activation lines

CAM

pCAM

Proportioning process, mixing, milling

Inter-process handling

Thermal processing operations

Drying

Calcination

WHAT WE OFFER

YOUR PRODUCTS

CATHODE AND INNOVATIVE MATERIALS

NMC, LFP, your innovation!

SAGGARS, REFRACTORY SUPPORTS

and other products related to battery production

SOLENOIDS, CELLS AND BATTERY COMPONENTS

EV BATTERY

solutions

HANDLING & ROBOTICS

We manufacture and provide handling and robotic equipment, and we incorporate traditional mechanical systems for the handling of saggars and other products associated with the CAM sector

PROCESS EQUIPMENT

As part of a turnkey plant provision approach, we offer, with help from our partners, the incorporation of the following equipment: proportioning, mixing, milling and magnetic separation.

CALCINATION & THERMAL PROCESSES

The raw materials essential for the manufacturing of the batteries, such as lithium, nickel, cobalt and manganese, must undergo an activation process. This process involves transferring material between the crucible and its contents, which requires both a drying stage and a firing stage. The handling of the crucibles before and after these thermal stages is also crucial.

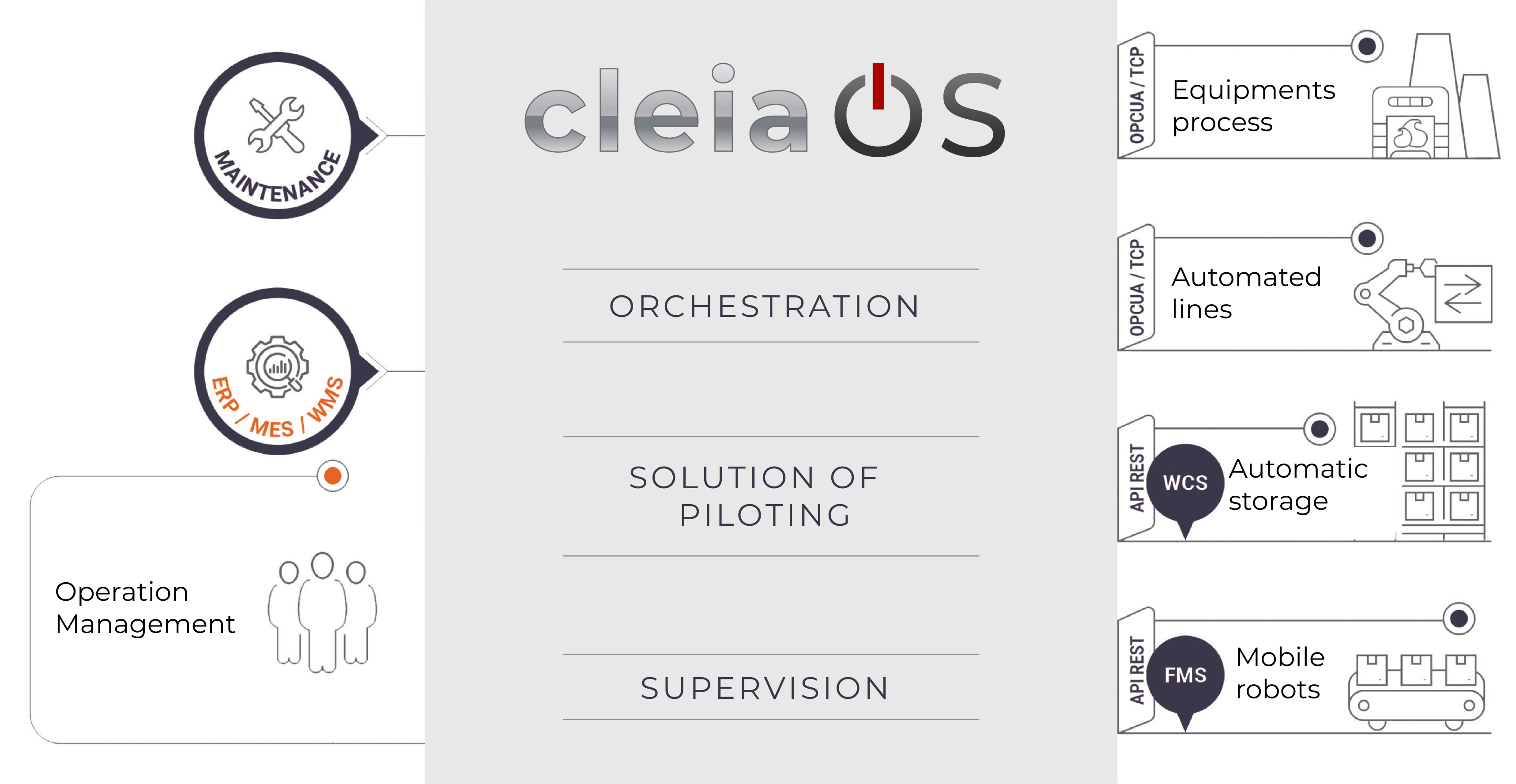

CLEIAOS, THE ORCHESTRATOR OF YOUR PRODUCTION

The advantages of cleiaOS

Explanation illustration of our cleiaOS production line orchestrator

cleiaOS offers key intuitive orchestration, optimised maintenance and global supervision functionalities, all with a no-code approach, thus facilitating the deployment and adaptation of the system.

With cleiaOS, our industrial IT solutions offer complete visibility of the operations, enabling better planning, real time monitoring and effective decision-making.

This allows for connected, reactive and quality-orientated plant management.

PARTNERS

BRANCHES

With the EV Battery activity, CLEIA is at the forefront of the electrical revolution, by providing our proven expertise and our passion for innovation to a rapidly evolving sector. We are enthusiastic about the idea of contributing to shaping the future of sustainable mobility.

AND AFTERWARDS?

Our ability to provide you with a complete after-sales service which covers many technical skills and has great reactivity, is one of CLEIA’s biggest strengths.